Are Custom Built Production Lines Worth The Difference in Price?

Buying the cheapest conveyor system might seem like you’re getting the best deal. However, a generic system can cost you money and time in the long run.

There are many benefits to systems with custom parts. For starters, they can improve how durable your production line is. They can improve the quality and efficiency of the manufacturing process. Plus, they can cut costs and increase profits over time.

Custom solutions will maximize quality and longevity. At the same time, they will minimize on price. However, it is important to know what a custom production line can do before you invest. Here, we’ve outlined some of the biggest differences when opting for a custom line.

Production Line Efficiency And Cost Savings

Generic production lines are only efficient up to a certain point. They are efficient for general manufacture processes. However, these processes won’t be tailored to your business and production needs.

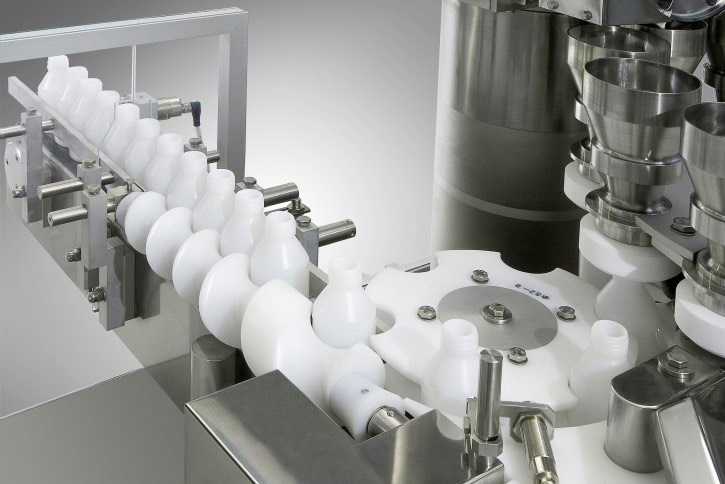

In contrast, a custom system can be uniquely designed to improve efficiency. One way of doing so is with customized timing screws. Timing screw manufacturers can create parts for specific container shapes. They also can produce unique screws for diverse functions. For each unique operation in your production, you can have a custom-tailored screw and function. This can ensure higher quality than a machine not customized to your company’s needs.

With custom parts, you can eliminate any excess or inefficient processes. Improved efficiency will lead to faster production. By customizing your system, your equipment can work quicker and save money.

Product Quality And Higher Profits

Another advantage of a custom system over a generic line is the difference in product quality. With a generic line, you are stuck with the manufacture stages that everyone else is using. With a custom line, you can change the small details of your production. This can lead to higher-quality results.

There are long-term advantages to improved quality. For example, a higher quality output will lead to better sales and reviews. In turn, this will generate higher profits.

Long-Term Longevity And Lowered Future Costs

With a customized system, you can have equipment that lasts longer. In turn, this lowers long-term costs. A custom system will better handle the workload that you expect it to complete. Plus, a unit designed uniquely to handle the speed and duration you need also will last longer. You’ll be less likely to need repairs or replacements, thus saving on costs.

You can have a variety of customized screw feed systems. These can include servo, stepper, brushless, and even explosion proof motors. These are more durable against possible malfunctions and engineered to handle the type of work you need. They can even be made to include stainless steel guards or vari-speed controllers.

Request A Free Quote!

If you are investing in short-term productivity and long-term savings, request a free quote today. Here at CSS Intl, we help to streamline production and maximize efficiency. Our timing screws can enhance the longevity, efficiency, and quality of your production.