Conveyor accessories to increase your line output up to 50%

A range of accessories that are ideal for almost every conveyor container application. Our products are easy to install and require low maintenance for ease of use.

Trusted quality

Our reputation is attributed to our dedication to superior quality in timing screws.

75+

Years In Business

50%

Line Output Increase

100%

Premium Accessories

Trusted and proven high quality by more than 2000 companies around the world.

Today, our timing screws, feed systems, change parts, bottom code/inspection diverters, lane combiners/diverters, product-oriented, side grip belt units, and vacuum reject systems are used by companies around the world to manage and manipulate containers and packages on their conveyor systems.

About Us

Improve Conveyor Line Efficiency

We are a private corporation always pushing the technical capabilities of our conveyor products in a constant effort to lead our industry to new and exciting possibilities.

- Competitive Pricing

- Excellent Customer Service

- Low Minimums

- Diverse Capabilities

Our Products

From high quality design and manufacturing to superior customer service, we provide the right solutions for all of your needs.

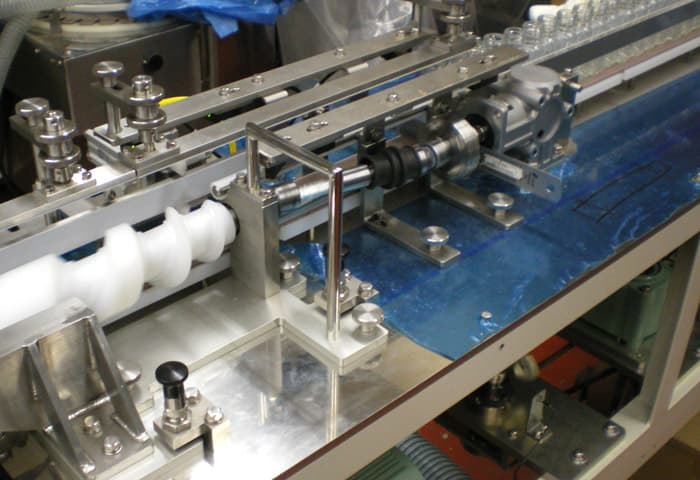

Timing Screws

Capable of designing and manufacture timing screws in a wide variety of materials and options.

Learn More

Screw Feeding Systems

Capable of customizing several individual components within our screw feeding systems for even greater effectiveness.

Learn More

Conveyor Change Parts

A variety of parts to improve your company’s production and to grow your bottom line.

Learn More

Bottle Lane Dividers & Combiners

Lane dividers and combiners that allow for easy division or combination of multiple lanes.

Learn More

Side Grip Conveyor Belt Units

Easy-to-install belt drive units that grab containers by their sides for gap transfer, bottom coding, inspecting, or labeling.

Learn More

Multi-Function Orienters

Our orienters can move or position a variety of container sizes, shapes and orientations for filling, labeling, and more.

Learn More

Vacuum Reject Systems

Precision-engineered vacuum reject systems that can separate products to specific destination lanes.

Learn More

Conveyor Metering Systems

Heavy-duty metering systems to help regulate conveyor item flow through the use of controlled gaps.

Learn More

View All

Browse all of our conveyor solutions.

About Our Company

CSS International was founded one month after World War II ended in October 1945 as a tool and die company specializing in engineering metal fabricated parts. During the late 1970’s the company shifted to the design and manufacturing of precision timing screws. Operating out of our own 28,000 square foot building, we celebrate over 75 years in business with products used by companies worldwide. We take pride in our engineering expertise which allows our customers to optimize the way they manage and manipulate containers and packages on their conveyor systems.