Timing Screws

When designing timing screws for our clients, we pay particular attention to the individual application for which they will be used. This ensures the timing screws offer the ideal product and performance for the job at hand. Following are just a few of the variations in timing screws we consider:

Container Shape: Timing screws are versatile. Whether the container/package shape is oval, rectangular, round, square, or triangular, we can produce timing screws to handle nearly any form. Moreover, we can also engineer timing screws that can cater to a family of related container shapes, allowing for greater application flexibility and offering significant cost savings.

Purpose: Our range of timing screws can accomplish many tasks. We can produce timing screws that allow for product collating, grouping, transfer, turning, orienting, dwell pocketing, acceleration, deceleration, combination, division, inspection, and labeling.

Line Type: Depending on the line type, whether it's Quick-Change, Dedicated, or Customized, we can produce timing screws to match the exact requirements.

Things You Should Know About Timing Screws

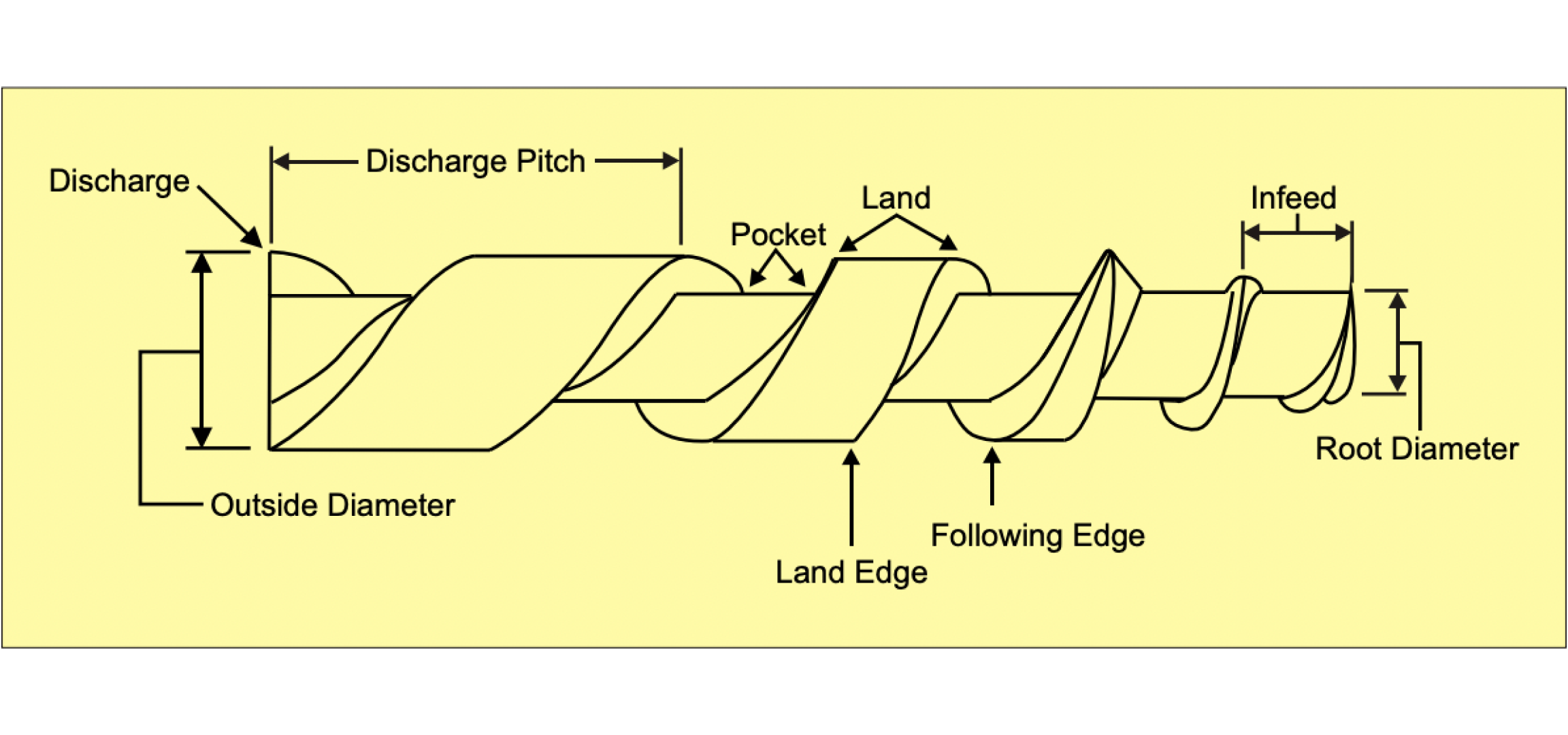

Timing Screws are a work of art. They should have graceful line and gliding movement of the container. The following items are most important in achieving quality and performance:

- Outside diameter of the existing screw

- Root diameter of the timing screw

- Length of the timing screw

- Rotation of the thread (left of right)

- Discharge spacing which is final pitch

- Line Speed CPM (containers per minute)

- Machine manufacturer’s name and model

- Shaft diameter (If there are any shoulders or relief portion on the shaft, please supply a sketch to note these conditions)

DISCHARGE SPACING - The final pitch of the screw thread is dependent on the type of machine and the operation to be performed. It is suggested that two (2) containers be submitted for final testing of final testing of the infeed and discharge threads of each screw ordered. If a screw is to be used on various containers, two of each size is required.

THREAD FEED - The rotation of the thread is vital. Please select the correct picture on the CSS Timing Screw Data Sheet. Any additional information or sketches that can be supplied will be extremely helpful.

MULTIPLE USE OF SCREWS - The general rule is a timing screw for each size container. However, timing screws used on circular containers can accommodate a variance up to (1) inch difference in the diameter size of the container. Rectangular containers and ‘F’ style cans require their own timing screws. It is normally accomplished when several container sizes in both categories and use in production. CSS personal will determine, at the time the containers are submitted for evaluation and testing, if the timing screw and accommodate different container sizes and shapes.

A Wide Variety of Timing Screw Material Options

CSS is able to design and manufacture timing screws in a wide variety of materials, including:

- Delrin

- Phenolic

- Hi Fax

- Ertalyte TX

- Nylon

- Steel

- Polyceram

- Brass

- PVC

- Aluminum

- Nylatron

- Chrome Plating

Types of Timing Screws

Left Hand Thread

Right Hand Thread

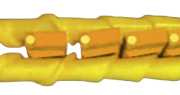

Straight Root

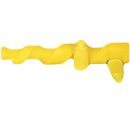

Inverse Taper

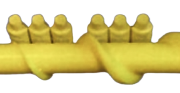

Double Pick Up

Double Thread Form

Transfer

Combining

Dividing

Turning

Shingle

Laydown

Collating

Dwell

Orientating

Cone In-Feed

Skip Load

Matched Pairs

Overhead Neck

Turnover with Guilde

Completely Customizable Timing Screws

Furthermore, timing screws can be customized to any number of factors, including Screw Diameters, Screw Lengths, Screw Rotation, Line Speed, Discharge Spacing, Mounting Hardware, and Live Conveyor Belt/Dead Surface options.

Thanks to our proven designs, quality materials and consistent manufacturing processes, CSS International is able to produce some of the industry’s best and most reliable timing screws. However, if any challenges were to arise, our customers can rest assured that we will be there to address and correct the situation. We stand behind everything we make and are ready to evaluate, design, deliver and maintain the right end product.

The Most Popular Timing Screws Designs

Timing screws have been a linchpin in companies' efficiency optimization, productivity, and accuracy enhancement for ages. Since each company has their individual timing screws needs, an expansive variety of screws have been innovated. With t he advancements in the industry, timing screws have become even more adaptable and essential.

Here's a comprehensive list of the most popular timing screw designs available today:

Inverse Taper Design

This type creates the highest performance when dealing with a random feed of containers, although it requires an offset guide rail

Straight Root Design

Standard Infeed

The basic straight root design features a constant root diameter that creates a smooth container infeed.

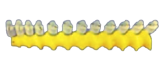

Shingle Infeed Design

This durable screw is best at separating flat sided and rectangular containers, even when faced with line backlog pressure. It is easily installed on labelers.

Non-Round Choke Design

Standard Infeed

This infeed design is used for separating square and rectangular containers, and it works most efficiently with a container backlog.

Dividing Timing Screws

Specific Function

This type is arguably one of the most useful designs as it evenly distributes one line of containers across two lanes.

Turning Timing Screws

Specific Function

Sometimes, rotating a container is necessary to carry out specific operations. Fortunately, turning timing screws have the ability to orient containers from 90 to 180 degrees to suit your orientation requirements.

Dwell Timing Screws

Specific Function

This particular design is made to allow a continuous flow of container while allowing containers to stop multiple times to perform different operations on the containers, such as cottoning, labeling, sleeving, closing, filling, or capping operations while the screws continue to rotate.

Combining Timing Screws

Specific Function

This handy design is utilized when two lines need to be converted into one output, for example, when you need to merge two lines into one.

Transfer Timing Screw

Specific function

Transfer screws give you the ability to keep control over containers as they are moved from operation to operation or machine to machine. These are not random fed, as the containers are placed directly into the timing screw pockets and depending on the size variations between containers the screw may be able to handle a larger family of containers.

Body and Neck Stabilizing Screws

Custom Timing Screw

When dealing with tall or unstable bottles or containers, stabilizing their body and necks becomes a vital part of your process. Fortunately, these screws are able to be mounted above each other to aid the stability of your containers.

There are a ton of timing screws design options available on the market today, so don’t limit yourself to simply the screws listed here. CSS International has developed a lot of experience installing, working, and maintaining timing screws over the years. If you have any questions regarding the type of timing screw you should be using, contact us today!

Why Choose Us as Your Timing Screw Manufacturer?

Having served over 100 clients worldwide, we house our operations in a sprawling 28,000 square foot headquarters, a testament to our expansive reach and capabilities. Our portfolio boasts a rich variety of services including screw feeding systems, conveyor change parts, bottom code, and much more.

- Competitive Pricing: Our pricing strategies are designed to provide maximum value, cementing us as a trusted partner in your supply chain.

- Customer Service Excellence: Our team is dedicated to providing unparalleled customer service, fostering long-lasting business relationships.

- Fast Turnaround and Low Minimums: We understand the urgency of your needs, offering fast turnaround times and accommodating low minimum orders to support businesses of all scales.

- Corporate Values and Guaranteed Quality: Rooted in corporate values that prioritize quality and customer satisfaction, we strive to exceed your expectations with every project undertaken.

Advanced Features of Our Conveyor System Solutions

From bottle lane dividers & combiners to multi-function orienters and vacuum reject systems, our offerings are engineered to meet a diverse array of industrial needs. Our portable side grip conveyor belt units and conveyor metering systems represent the pinnacle of innovation, designed to integrate seamlessly with existing setups and enhance operational efficiency.

Industries Benefiting from Our Timing Screw Innovations

Our timing screw solutions find applications in a myriad of industries including food and beverage, pharmaceuticals, packaging, and more. Our long-standing experience as a timing screw manufacturer empowers us to deliver solutions that are both cutting-edge and reliable, fostering a smoother, more efficient production line.

We invite you to explore the stories of numerous satisfied clients who have leveraged our expertise to revolutionize their conveyor systems. Our reputation as a reliable timing screw manufacturer is echoed in the glowing testimonials from industries we have served.

Join the ranks of businesses worldwide who have transformed their operations with CSS International Corporation, where innovation meets reliability in conveyor system solutions. Contact us today to find out how we can help elevate your business to new heights.