Everything You Didn’t Know About Timing Screws

In the intricate world of conveyor systems, timing screws stand as unsung heroes, ensuring efficiency and precision. At CSS International Corporation, with our extensive experience in conveyor system solutions, we've come to appreciate and master the art of integrating timing screws for optimum performance. This article delves into the world of timing screws and why they are paramount in modern conveyor systems.

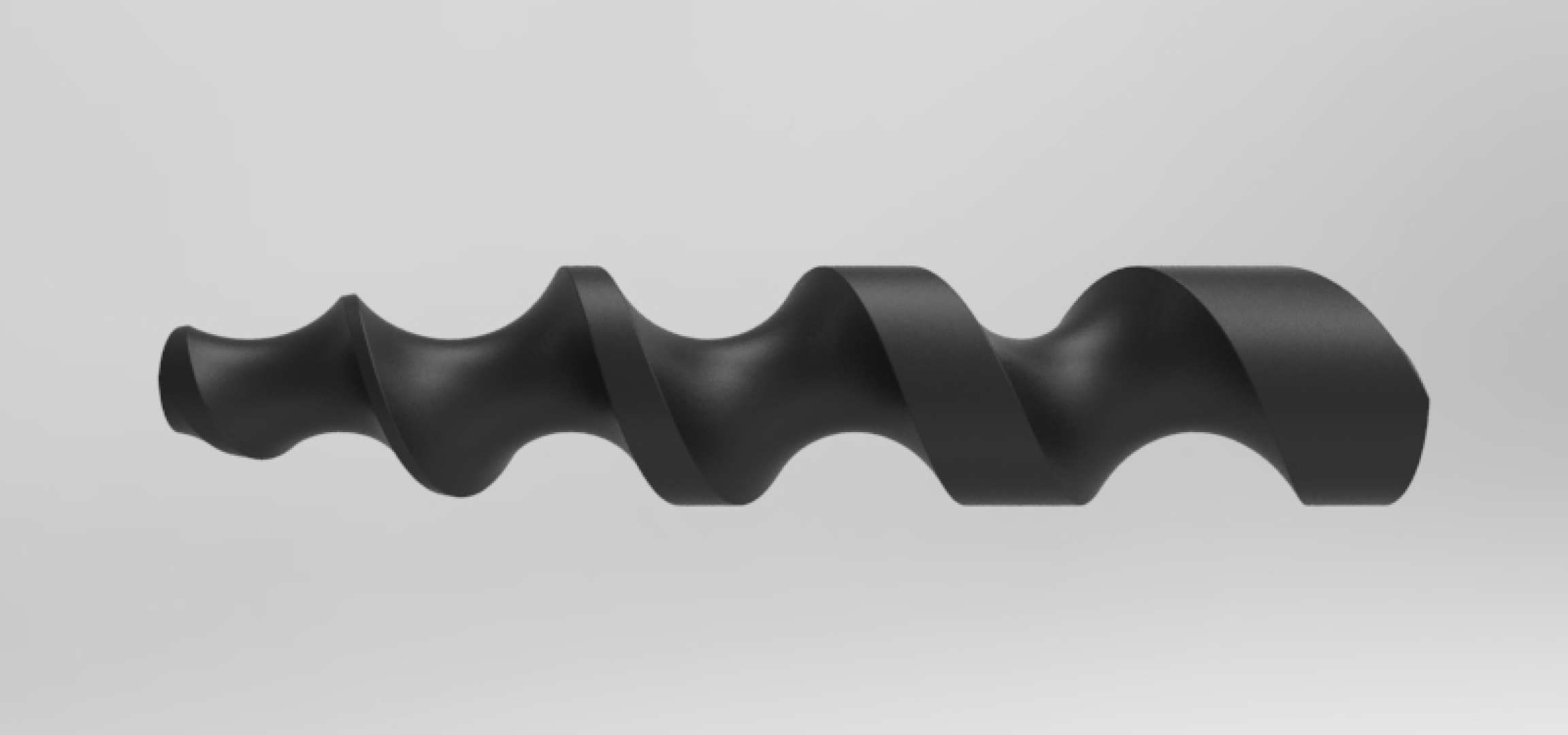

The legacy of timing screws stretches back over decades, evolving with technology and industry demands. Fundamentally, these screws are designed to move and guide products, ensuring they are positioned correctly as they move along a conveyor line. Made of varied materials and designs, timing screws have become a staple for industries, and few understand them better than CSS International Corporation.

How Timing Screws Work: The Technical Aspect

The mechanics behind timing screws is what sets them apart. Their primary function is to move and guide products seamlessly. Different materials like stainless steel or plastic can be used in their manufacturing, depending on the application and industry needs.

Recent advancements have further refined their designs, making them more adaptive and efficient. For a company like CSS International Corporation, with 75+ years in the business, staying at the forefront of these technological advancements is second nature.

Applications: Where Are Timing Screws Used?

While timing screws have a broad range of applications, some of the standout industries include:

- Packaging: Ensuring products are aligned and ready for packaging.

- Food & Beverage: For precise movement of food items, ensuring hygiene and efficiency.

- Pharmaceuticals: Where precision and sanitation are of utmost importance.

CSS International Corporation has catered to over 100 clients worldwide, helping industries harness the power of timing screws to the fullest. One of our case studies showcases a pharmaceutical company where timing screws revolutionized their production line, making it 30% more efficient.

Benefits: Why Choose Timing Screws in Conveyor Systems?

Here's why CSS International Corporation champions the use of timing screws:

- 1

Efficiency: Timing screws offer unparalleled efficiency in product handling and separation.

- 2

Durability: Given their robust design, timing screws are built to last.

- 3

Customizability: With diverse requirements across industries, timing screws can be tailored to fit specific needs.

- 4

Cost-effectiveness: Over time, the ROI of integrating timing screws is significant.

Future Trends: The Evolution of Timing Screws

As technology evolves, so does the potential of timing screws. We foresee:

Advanced integration with AI and IoT, allowing timing screws to be more adaptive and smarter.

A focus on sustainability, with eco-friendly materials and energy-saving designs becoming the norm.

Having been in the industry for over seven decades, CSS International Corporation is committed to being at the vanguard of these changes, ensuring our clients always get the best solutions.

Tips for Selecting the Perfect Timing Screws for Your Operation

At CSS International Corporation, we often guide our clients through this selection process. Here's what we recommend:

- 1

Understanding Needs: Gauge your product and conveyor needs first.

- 2

Quality Assessment: Always ensure that the timing screws you choose are of top-tier quality.

- 3

Reputation Matters: Opt for manufacturers and suppliers with a proven track record. With 75+ years in business and a 28,000 square foot headquarters, we at CSS International Corporation stand testament to quality and commitment.

Timing screws are more than just components in a conveyor system; they are the heart that ensures the system's rhythm and efficiency. For businesses looking for impeccable quality, extensive experience, and unwavering dedication, CSS International Corporation remains the go-to choice.

With competitive pricing, customer-centric service, low minimums, and a guarantee of quality, we make sure our clients get the best in the business. Our vast array of services, from Screw Feeding Systems to Engineering Services and Conveyor Accessories, only reinforces our commitment to diverse capabilities and guaranteed quality.