How Common Are Timing Screws Malfunctions and How to Repair Most Common Ones?

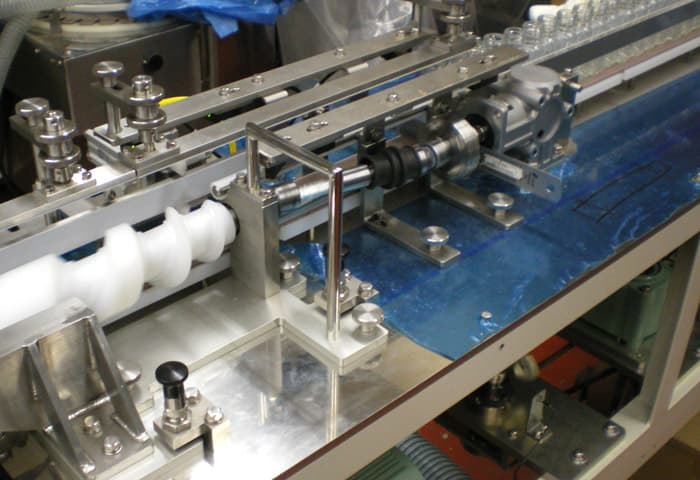

Timing screws are made to support specific operations on a packaging production line. They meter the containers on the line to ensure that each container precisely passes through machines on the production line. These machines perform functions such as labeling, bottle capping and inspection. While timing screw operation is not performed by human beings, humans do oversee the production of the line. Even then, timing screws occasionally can malfunction. Here are some common reasons why:

Having the Incorrect Screw on the Machine

Having the correct screw is crucial to the operation that is to be performed. We suggest that screws be properly marked to ensure that the right screw is used for the specific machine.

Using Too Many Screws

As a rule of thumb, we recommend using one screw for each container size. However, depending on the number of containers in a family of products, one screw may be sufficient to handle the group. This will result in reducing the costs for change parts and inventory. Should you have a project using multiple container sizes, contact one of our staff to review your specifications and determine the minimum number of screws the project requires.

Speed That Doesn’t Match the Screw Type

When timing screws are designed, one must take into consideration the container details, line speed in containers per minute (CPM), required discharge pitch and the conveyor belt speed. Also one must know the type of machine and the style of timing screw drive on which the screw will be mounted. Once all the line specifications are known, a suitable timing screw can be fabricated provided the container details do not exceed the capacity of the specific machine.

Rotation of Thread Is Faulty

The rotation of the thread of the screw could either go left or right. Know the direction of the rotation you need. This will save a headache from the get-go. If you are unsure of the required rotation, review the CSS Timing Screw Data Sheets on our website or feel free to contact our staff for assistance.

Containers Per Minute Information

Make sure you’ve determined the exact containers per minute the screw is supposed to handle. This is vital information. An additional factor to consider is whether the screw will run continuously or in an indexing application. Also one must consider the conveyor belt speed to make sure it suits the specifications of the timing screw manufacturer.

Overall, stopping your timing screw for any repairs can take away from your business and cost you money in parts, repairs, and even labor. Before you run into any problems, we’re here to help.

How CSS International Can Fix Your Timing Screw Malfunctions

At CSS International, we specialize in conveyor systems solutions. Founded just after World War II, we serve companies around the world to run and handle containers on their conveyor belts.

With over 70 years of experience, we have adapted to this world of technology, while remaining a leader in the conveyor systems industry. From timing screws to product orienters, bottom code/inspection diverters, and more, we know how to assist your company with your conveyor needs. Contact us to request a free quote today! We’re here to stay and we value the professional relationships we build with our business partners. Additionally, we treat our customers right with individualized attention, respect, and care. Give us the chance to take care of your conveyor system needs!