6 Reasons Why Installing Timing Screws Brings Maximum Value to Your Conveyor Line

If you operate a conveyer line, chances are that you spend a lot of timing determining what helps maximize its value and productivity. And you should! This helps to ensure that you’re getting things done in the fastest and most effective way possible – putting the most money in your pocket at the end of the day.

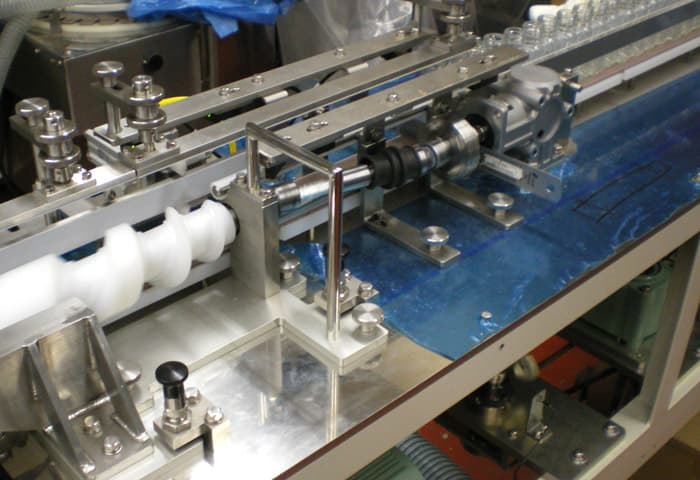

Timing screws are a great option to help you maximize the value of your conveyor line. They can help to increase your productivity in a wide variety of ways and give your conveyor line the best results! Here’s everything you need to know:

1 – Increases Line Speed

Timing screws increase how quickly you are able to produce products by increasing the product line’s speed. You’re able to push through more products in less time. While the speed is very quick, these mechanisms are built to offer a smooth flow, so you’re increasing speed without compromising quality.

2 – Uncompromised Accuracy

In a very short period of time, timing screws are able to offer accuracy in a split second. This is critical for the success of your conveyor line, making timing screws an essential aspect of your production. While they are designed for maximizing your performance, they also optimize efficiency.

3 – Prevents Mistakes During Production

Because this innovative technology is so sophisticated and advanced, timing screws are able to result in fewer mistakes in your production line. They are efficient workers that ensure your packages won’t need to be double checked!

4 – Reduces the Risk of Downtime

As someone who runs a conveyor line, you know how costly downtime can be for your organization. With timing screws, you can make the most of the value of your machine. They effortlessly eliminate errors and reduce your chances of expensive downtime. Don’t let your company lose any more money as a result of wasted production time that results from errors!

5 – Minimize Noise

Do you find that your conveyor line is an environment with loud noises and unexpected errors? This comes with the nature of a place with such high demands – but timing screws can help to lessen this problem. By working quickly and efficiently, you won’t have all that unnecessary noise that comes with production. This means that, by producing more, the result won’t be a noisy and hectic working space.

6 – Cost Effective

Timing screws help to save your organization money in the long run – by increasing your production speed and cutting down on downtime. This inexpensive solution is cost-effective and ends up saving you more money than you could have imagined as time keeps going on.

The Verdict

As you can see, there are a lot of benefits to enjoy that come with adding timing screws to your conveyor line – with no downsides! With timing screws being an inexpensive and effective solution that increases accuracy, speed, productivity, and reduces downtime, it’s hard to understand why anyone would decide not to have them as part of a conveyor line.